A high-performance, precision-engineered in-line system filter, the TF1 Sigma Filter utilises a sealed, lidless design for increased reliability and strength. Ideal for use in restricted spaces due to its capability of being positioned in multiple orientations up to 45⁰.

This simple to install, composite plastic filter fits onto vertical and horizontal pipework, and works by allowing Hydronic Particle Separation (HPS) action to deliver contaminants to the unit’s powerful magnet assembly for safe removal.

The TF1 Sigma Filter is constructed from a high strength engineering polymer, suitable for heating and cooling system applications. The glass reinforced polymer has good hydrolysis resistance, as well as high resistance to strain and abrasion. The polymer is compatible with glycols and additives used in central heating systems.

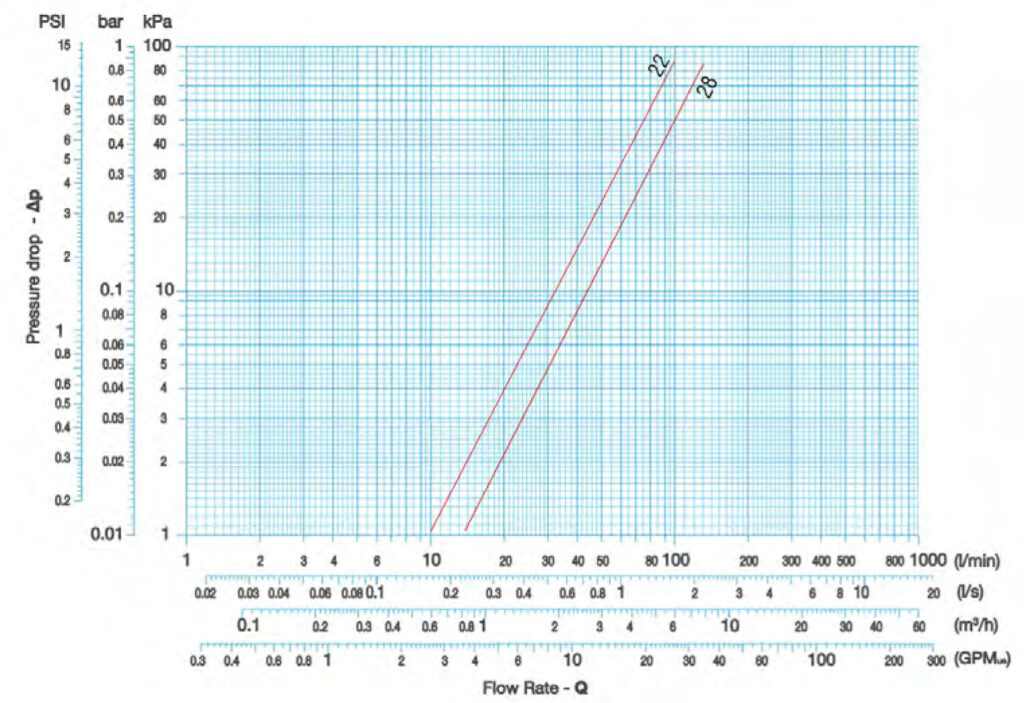

The TF1 Sigma Filter has been designed to ensure there is minimal pressure loss in addition to maintaining a high collection efficiency. The internal HPS, magnet assembly and area of low flow have all been engineered to allow the filter to capture a range of system contaminates, whilst not impacting the rest of the heating system.

The TF1 Sigma Filter utilises a range of high-quality component parts that ensure the filter offers optimum performance. The magnet is manufactured using a premium grade of neodymium, enabling a high efficiency capture rate, as well as a robust filtration medium that will ensure a continued and consistent level of collection.

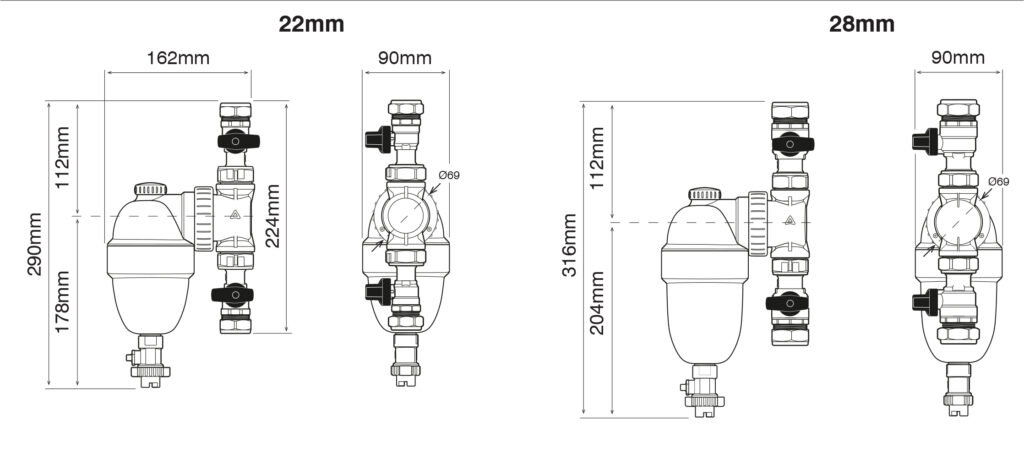

Product Code | Type | Size | Single Unit Dimensions(Height x Width x Depth) | Single Unit Barcode | Outer Carton Dimensions(Height x Width x Depth) | Outer Carton Barcode (ITF) |

|---|---|---|---|---|---|---|

62414 |

Slip Socket |

22mm |

115 × 255 × 180 mm |

5014551624146 |

241 x 362 x 268 mm |

50145510017010 |

62415 |

With Valves |

22mm |

115 × 255 × 180 mm |

5014551624153 |

241 x 362 x 268 mm |

50145510017188 |

62417 |

With Valves |

28mm |

112 × 346 × 179 mm |

5014551624177 |

241 x 178 x 352 mm |

50145510017256 |

© Fernox 2024. All rights reserved